Intelligent Compaction - Our solution for optimum compaction control with innovative fleet management.

Every day, construction companies face certain challenges in compaction that need to be mastered. Cost and time pressure, as well as quality requirements, are at the forefront. Machine controls from MOBA help to master these challenges by increasing performance and ensuring quality.

|

|

|

|

|

Thanks to its innovative fleet management the crossings of different rolls are synchronized with each other, so that each passage is optimally compacted. This automatic coordination ensures all-time highest quality and allows the use of multiple rollerss and operators at the same time! Thus, large projects are implemented in the shortest possible time and extremely cost-effectively.

With our high-end operand, the entire process is visualized, thereby helping you to keep control of the number of crossings at all times.

Thanks to an unproblematic display of measurements, the proper interpretation of the measured values are learnt intuitively and quickly. The MCA measures values like the stiffness, the frequency of the drum, the amplitude & the temperature of the asphalt.

The 4-button design allows an incredibly intuitive and efficient operation of the MOBA-Matic II. The backlit keys also make night work possible. The unique housing design is also functional according to the motto "form follows function" and therefore allows a very good grip.

As a proof of quality all compaction data is also summarized and retrievable from a web server on demand at any time. Even when you have worked on a fleet project, this is summarized in a report with data of the whole fleet.

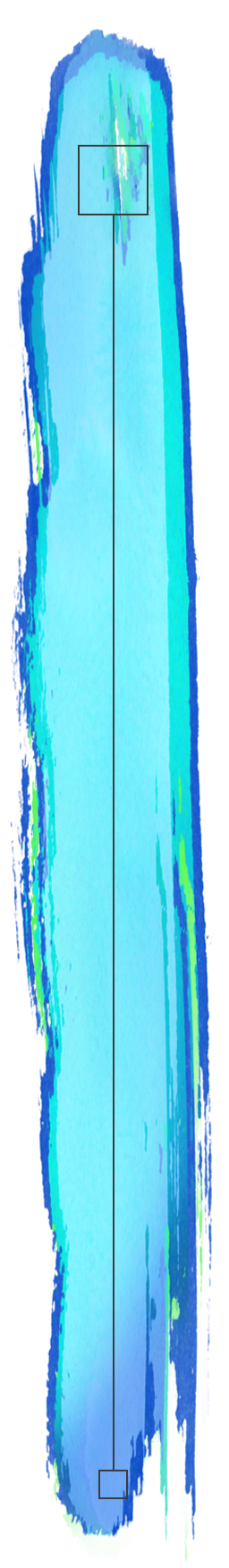

EXTENSION 100M

WIDTH 1,5M

10M FROM BEGINNING

50M FROM BEGINNING

10M FROM THE END

The operator was instructed to compact according the jobsite definitions to reach the maximum compaction. In this test track 16 passes were executed. After 16 passes, the laboratory did compaction test in the jobsite.

Even after the 16 passes the soil didn't reach the compaction degree of 100%. This fact can be explained by some hypotesis:

EXTENSION 100M

WIDTH 1,5M

10M FROM BEGINNING

10M FROM THE END

The operator was instructed to compact untiel the map progress exhibited in MCA-3000 display was green. Many test tracks were executed with MCA-3000 orientation, considering some material.

After only 8 passes the soil reached its maximum compaction capacity, saving 8 passes in vibratory mode.

*Based on a test by MOBA do Brasil on a test distance of 100m. Both test runs were performed under the same conditions.

Define target values for passes to roll over the road. The color symbolizes the compaction values. The system recognizes if the values are not changing anymore, then the pass is shown in green color. No further compaction can be achieved there. A perfect compaction result is therefore achieved.

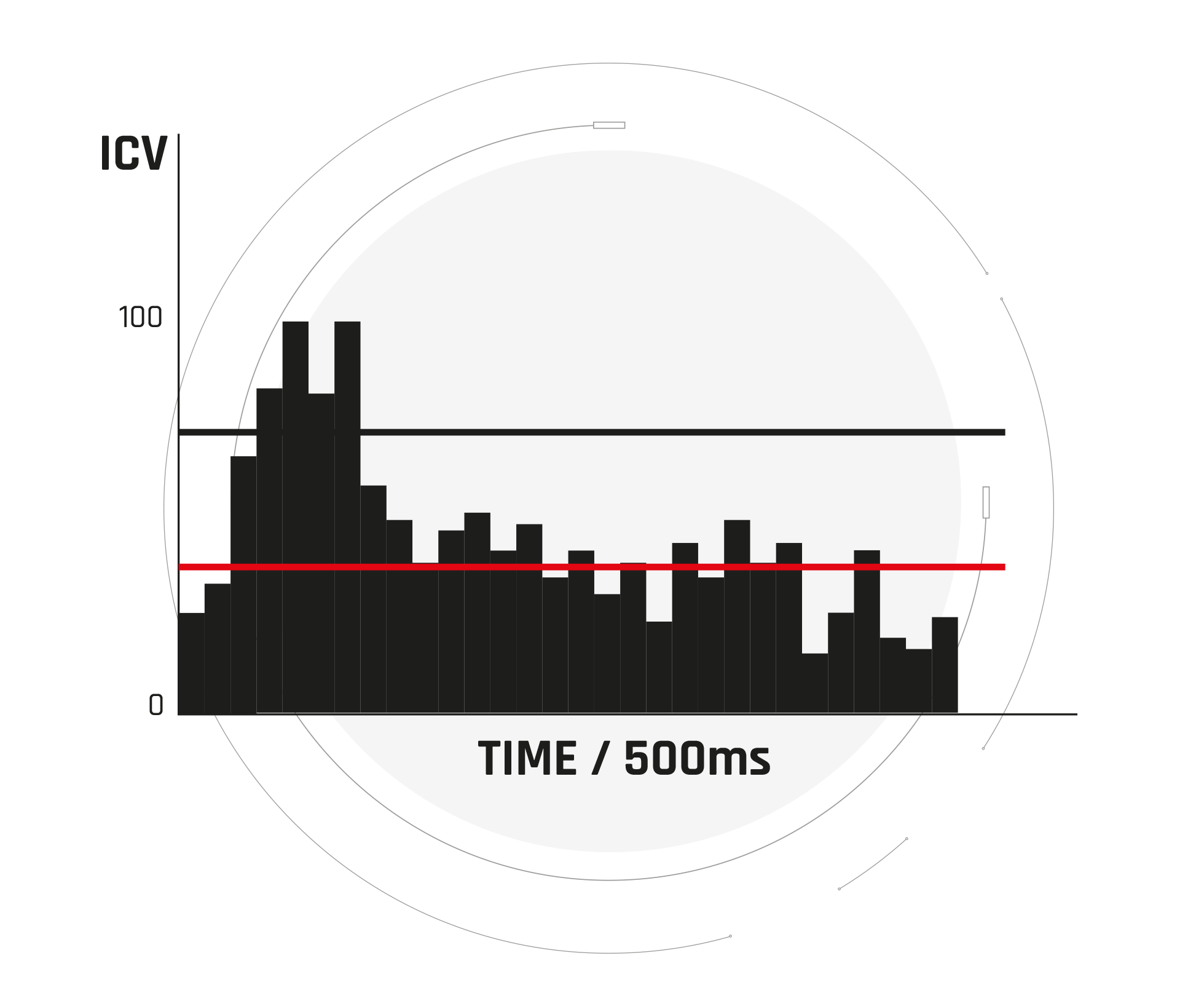

The ICV is the relative performance indicator for road density. It measures the status of the compaction progress. The absolute value of the ICV changes with the consistency of the material and the underground. The ICV verifies the constant compaction of the material during operation.

Modularity guarantees

|

With the MCA-500 or MCA-3000 system, you are always optimally equipped for all the requirements of a construction site. MOBA paving quality systems guarantee a precise and efficient result for your individual project through the perfect interaction of all components. |